COEXCA S.A. is Chile’s second largest pork meat production and processing company. The company’s activity covers the entire production process, including feed production and processing plants. A critical factor is the quality of the feed water, which is highly dependent on the level of free chlorine in the water. The acceptance range for free chlorine in feed water is 0.3 to 0.5 parts per million (ppm). Failure to maintain this range can lead to serious animal health and quality issues. Therefore, compliance with this range is crucial for companies producing pork meat related products. To measure this threshold, COEXCA S.A. previously used a system that was not precise enough and required a lot of maintenance and calibration.

In order to meet the required factory standards in the production processes, the company needed a fully automated and integrated measuring and dosing system for the amount of free chlorine in the water, capable of generating accurate and reliable control data. This required replacing the old and inefficient manual devices with a high-quality measuring system and dosing pumps capable of generating accurate and reliable data without major intervention.

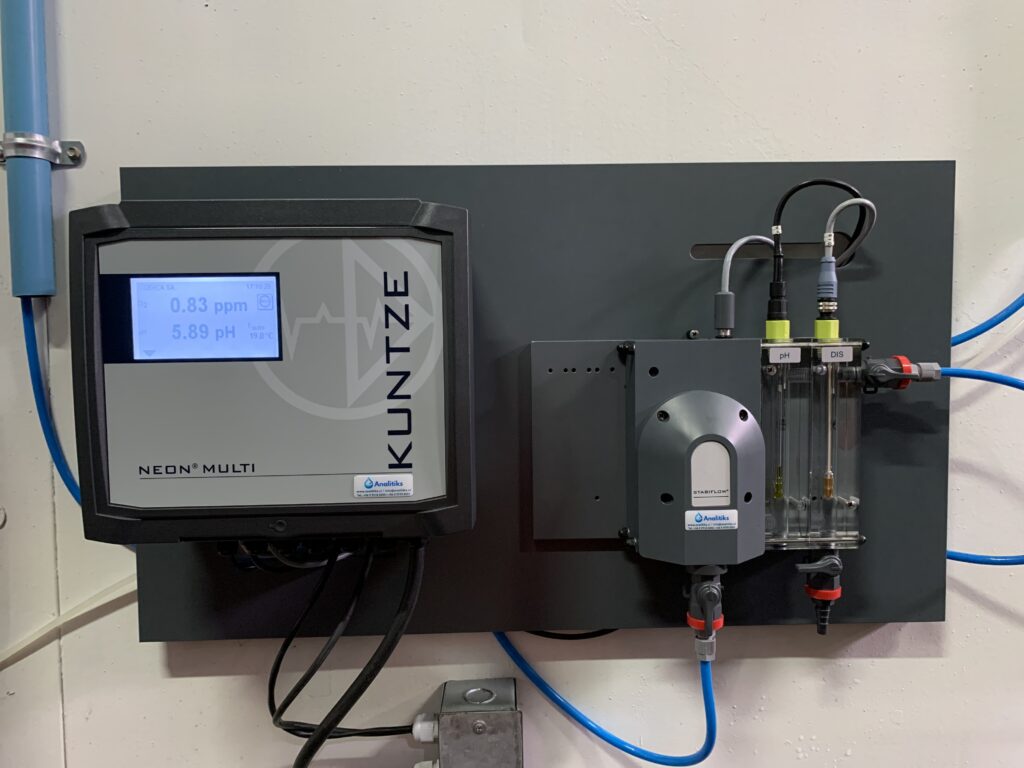

Kuntze’s Krypton® Multi multi-channel water monitoring system provided the perfect solution to this challenge of controlling the free chlorine in feed water. Uniquely, the Krypton® Multi system, through its Stabiflow® unit, is able to keep the water flow constant automatically and without manual intervention. This reduces maintenance time and costs for system calibrations Due to the use of highly accurate sensors, the Kuntze Krypton® Multi is also much more precise and reliable in the measurement performance. Immediately after installation and commissioning, the system succeeded in maintaining the chlorine measuring range within the plant according to the required plant standards. Further statistical testing confirmed this initial good performance by showing only minimal differences in measurements and maintaining an error of only ±2% of the measurement range. The confidence in a more accurate, stable and automated system, and in Kuntze, as one of the world’s quality leaders in water analysis, allows the company to significantly reduce the workload on its employees and save on labor costs by reducing manual effort while ensuring high quality feed water.

COEXCA S.A. is Chile’s second largest company in the production, processing and marketing of pork meat. Founded in 2002, COEXCA S.A. covers the entire production process, from feed production, pig breeding, processing plants and logistics to the final consumer. With the vision of being recognized as a leader in the global food industry, the company has opened commercial branches in Asia and Europe and, after almost twenty years of activity, sells its pork cuts in more than thirty countries. Today, Coexca S.A. has a modern processing plant of more than 15,000 square meters on 18 hectares of land and employs 700 people. Through its various processes, the company is passionate about maintaining the highest standards of food safety, service quality and environmental protection.