A pet food processing plant in Nebraska uses Hydroflex cooling tunnels, which have 3 washing and rinsing zones with a tank capacity of about 2,000 gallons. The Food and Drug Administration ‘FDA’ requires a minimum residual of 0.3 ppm free chlorine in the wash zones. If the minimum residual drops below 0.3 ppm the batch either needs to be reprocessed or discharged. The plant was using an amperometric online analyzer to control and to monitor the residual of two biocides (12.5% bleach and 40% activated bromine), which was fed at a 10:1 ratio into the tank of the Hydroflex cooling tunnel.

Due to the high organic contamination of the cooling water, the sensor of the competitor analyzer fouled quickly, causing drifting and residual control issues. Since it became very difficult for the plant to maintain a consistent target residual of 1 ppm, the plant decided to implement the following measures to reduce the speed of the sensor fouling:

Despite the implementation of those measures, the plant still experienced control issues requiring emergency interventions, which also sometimes occurred over the weekends when limited operator resources were on-site. The plant was also concerned about the possibility that the oxidizer residual might fall below the minimum FDA threshold of 0.3 ppm.

The pet food processing plant asked Kuntze’s distributor to resolve the problem by plementing another solution. The distributor suggested an amperometric measurement system from Kuntze Instruments. The analyzer uses a solid-state bare sensor with two gold band electrodes for easily interpretable measurements. The gold electrodes provide excellent chemical selectivity, enabling the analyzer to reliably measure small changes in the biocide residual. The sensor also features Kuntze’s Automatic Sensor Cleaning technology (ASR®), which can be triggered up to seven times a week, depending on the fouling level. The distributor installed the Kuntze analyzer monitoring the biocide levels in the 2nd zone of one of the Hydroflex cooling tunnels parallel to the existing analyzer.

Operators took manual DPD tests three times per day to compare the reading with both online analyzers. The plant also monitored the residual deviations from the 1 ppm target.

The Kuntze analyzer outperformed the previous system by delivering consistently reliable measurements while significantly reducing the required preventative maintenance and operational expenses. Through the use of their remote monitoring tool Cloud Connect®, the Kuntze Instruments team was able to track the progress and success of the trial by interpreting the sensor signal compared to the reference measurements provided by the plant.

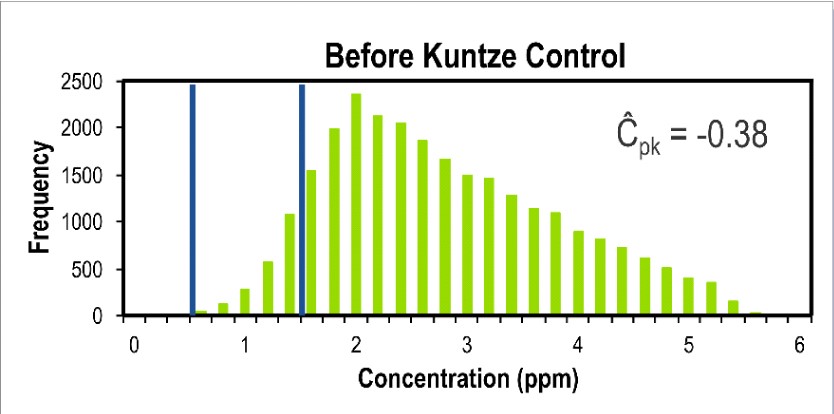

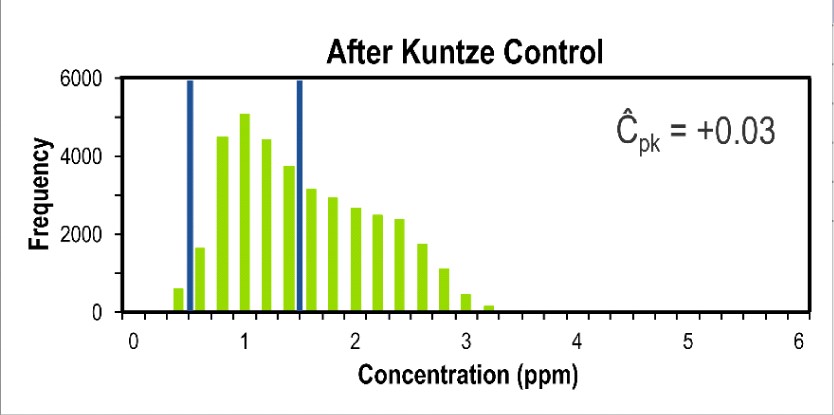

To compare the performance of each system, Kuntze Instruments calculated the process capability index (Ĉpk) of the process before and after the plant switched to control by the Kuntze analyzer. The Ĉpk shows how closely a process stays between an upper set limit (USL) and a lower set limit (LSL), and process capability improves as Ĉpk increases. In the context of biocide control, Ĉpk reflects how well the biocide residual stays close to a specified target (between the USL and the LSL) with little to no fluctuations.

Before the dosing pumps were controlled by the Kuntze analyzer, the biocide residual did not fall between the USL and LSL (Ĉpk = -0.38). After the plant switched to Kuntze control, the average biocide residual fell within the specified limits (Ĉpk = 0.03). The increase in Ĉpk indicates that controlling using the Kuntze analyzer improved the process and brought it into compliance.

Because of the addition of the Kuntze analyzer, there were significant cost benefits for the plant:

Based on the trial results, the pet food processing plant decided to replace all analyzers with Kuntze technology.