Uma pequena estação de tratamento de água potável utiliza águas subterrâneas e superficiais como água bruta em seu processo de tratamento. O analisador da Hach Cl17 não performou neste ambiente devido às rápidas mudanças nas concentrações de desinfetante e ao manganês pesado, criando falsos positivos na medição. Enquanto isso, usar um sensor de membrana seria muito caro para a planta devido. A solução da Kuntze eliminou a necessidade de tamponar o pH e de altos custos de consumíveis e reagentes utilizados nas tecnologias concorrentes. Além disso, o Cloud Connect® foi capaz de otimizar os processos do cliente e fornecer uma solução de conformidade real, economizando tempo e dinheiro para a estação de tratamento de água.

COEXCA S.A. is Chile’s second largest pork meat production and processing company. A critical factor is the quality of the feed water, which is highly dependent on the level of free chlorine in the water. To measure this threshold, COEXCA previously used a system that was not precise enough and required a lot of maintenance and calibration.

Voens S.p.A. is a company headquartered in Santiago, Chile that provides water conditioning equipment and water purification systems. As such, in all of their production processes the amount of free chlorine in the water must be strictly between 0.3 and 0.5 parts-per million (ppm). For measuring this threshold level, the company previously made use of mechanically cleaned sensors.

A Canadian drinking water facility experienced heavy, naturally occurring iron and manganese concentrations in their ground water source.

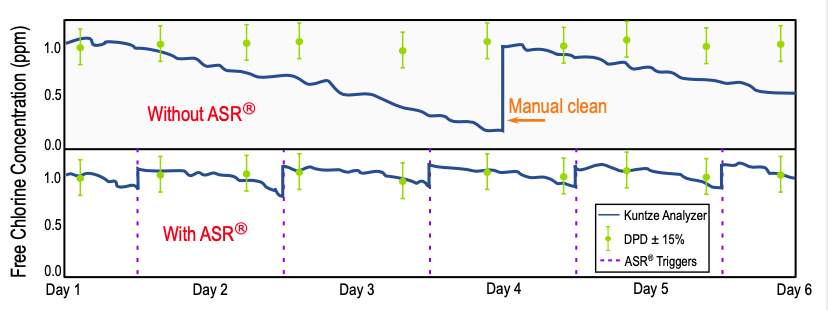

A common water quality characteristic found across many water treatment markets. Months after initial install, heavy compounds removed due to Kuntze patented ASR® technology.

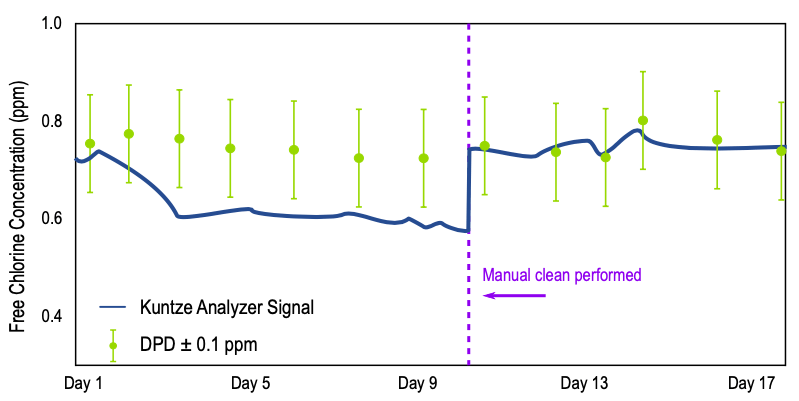

This analyzer was installed in a drinking water application sourced from ground water using free chlorine chemistry.

The ground water source contained high amounts of iron and manganese, which fouled the probe. The operators in charge of the equipment found themselves frequently manually cleaning the probe. After using Cloud Connect® to view and analyze the data, Kuntze Trial Managers instructed the customer to increase the Automatic Sensor Cleaning frequency to one cleaning per day.

Um sistema público de água potável (DWS) localizado em Alberta opera duas estações de tratamento de água potável de nível 2, uma estação de tratamento de água potável de nível 3 e três sistemas de armazenamento de água potável. Foram usados um sensor amperométrico coberto por membrana e um sensor colorimétrico, ambos on-line, para controlar e monitorar os níveis residuais de cloro livre em seus sistemas de água potável. Enquanto ambos os analisadores foram capazes de permanecer na faixa alvo de residual, o sistema Krypton® Multi teve, em média, menos desvios das medições de referência, fornecendo leituras mais precisas.

This analyzer was installed in a drinking water application using free chlorine chemistry. The customer noticed that the analyzer signal was consistently lower than their reference measurements. According to USEPA 334.0, their analyzer signal had to be within ± 0.1 ppm of their reference measurements to stay in compliance. After using Cloud Connect® to view and analyze the data, Kuntze Trial Managers instructed the customer to perform a manual clean of their Zirkon® DIS probe.

This recommendation could not have been made without using Cloud Connect® to visualize the data.

A Duncan Family Farms®, uma produtora familiar, anunciou hoje a instalação de um sistema de tratamento altamente eficaz, controlável e portátil para água de irrigação. A instalação, incluindo cinco sistemas em culturas de folhas orgânicas no Oregon, representa o primeiro uso no segmento agrícola de sistemas de tratamento de água da Kuntze Instruments da Alemanha. “Estávamos procurando a melhor solução para atender com segurança aos requisitos de saneamento da Leafy Greens Marketing Association (LGMA) recentemente adotados para água de irrigação, e a Kuntze apresentou uma tecnologia impressionante que poderia impactar positivamente nossas operações em crescimento e toda a indústria de produtos frescos,” disse Jeremy Vanderzyl, Diretor de Serviços Técnicos.

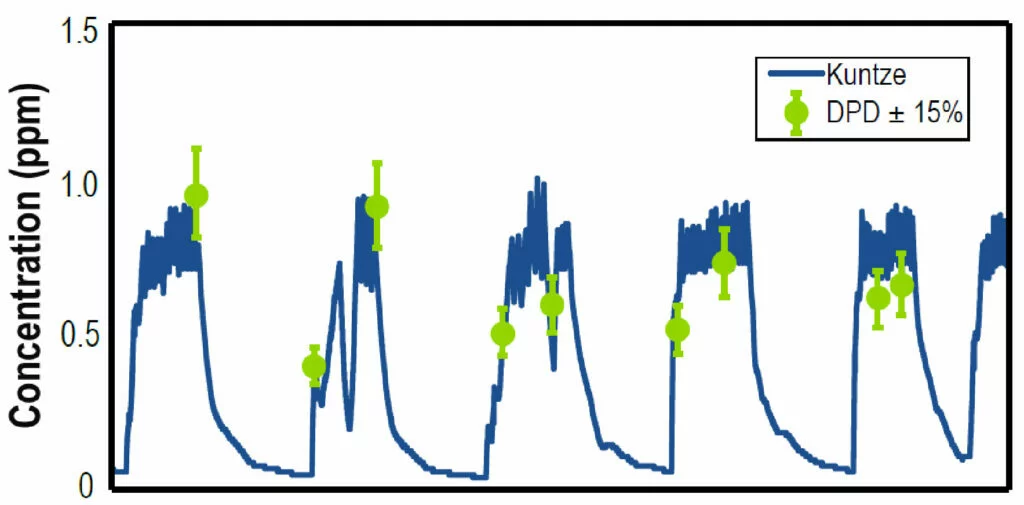

This analyzer was installed on a cooling tower using free chlorine and activated bromine chemistry.

The operators noticed that they were having a hard time meeting their minimum target oxidant residual. Around the same time, the operators also noticed a large drop in their ORP measurement. Using Cloud Connect® and input from the tower operators, the Kuntze support team looked further into the issue

With the Cloud Connect® service, Kuntze has created a solution that enables central administration and sensor analysis. The Kuntze measuring devices communicate with each other via a bus system and send data to a secure cloud storage using the Kuntze Cloud Connect® gateway, either via 4G or local internet connection.

The Cowichan Valley Regional Water District operates 17 surface and ground water systems and 2 reclaimed wastewater treatment plants. The district previously used 7 membrane analyzers from Severn Trent Services Capital Control® to monitor the free chlorine residuals in the storage tanks and at the end of the drinking water discharge lines. The analyzers experienced drift due to the challenging water conditions and required at least one calibration per month.In order to improve measurements and to reduce preventative maintenance, ClearTech suggested the installation of the Kuntze Krypton® Multi analyzers to monitor the free chlorine residuals. The district liked especially Kuntze’s Automatic Sensor Cleaning technology (ASR®), which automatically runs up to once per day preventing the sensor from fouling.

Through this case study, we hope to demonstrate the viability and utility of bare amperometric sensors for measuring stabilized bromine concentration in industrial cooling towers.

To demonstrate that bare amperometric sensors could accurately measure stabilized bromine products, we installed a sensor in a 200-ton cooling tower at an industrial plant in the suburbs of Chicago. The cooling tower for this case study is timer-fed, meaning a highly concentrated solution of biocide is introduced at the beginning of the tower’s operation cycle and is consumed as the tower runs. For the second phase of the study, we established control using a chemical dosing pump that is directly informed by the bare amperometric sensor signal.

A public ground drinking water system (DWS) located in the Pacific Northwest serves about 15,387 connections. The DWS treats the spring water with chlorine gas and for the seasonal-operated wells either liquid or solid chlorine systems are used.

The Kuntze Krypton® Multi System reliably controls the disinfectant residue so that DWS can continue to use Correct Equipment’s preferred chlorine tablet system.

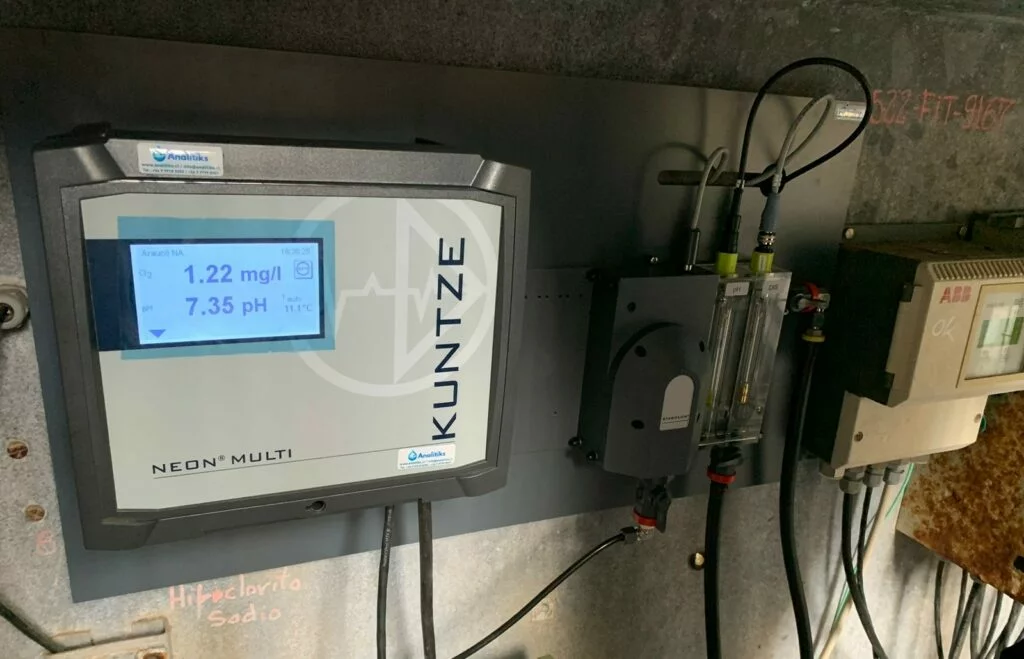

Celulosa Arauco y Constitución S.A. is a global company headquartered in Santiago, Chile that develops quality products based on renewable forest resources such as pulp, coated boards or moldings. For all its production processes, the amount of free chlorine in the production water must be strictly between 0.8 to 1.2 parts-per million (ppm). For measuring this threshold level, the company previously made use of mechanically cleaned sensor, which was not sufficient and required frequent manual cleaning and calibration.

For more efficient and precise measurement of water quality, the Chilean Kuntze partner “Analitiks SpA.”, installed a Krypton® Multi multi-channel water monitoring system for the measurement and control of free chlorine and pH at Celulosa Arauco y Constitución S.A. In doing so, our partner was able to solve our client’s challenges with great success.