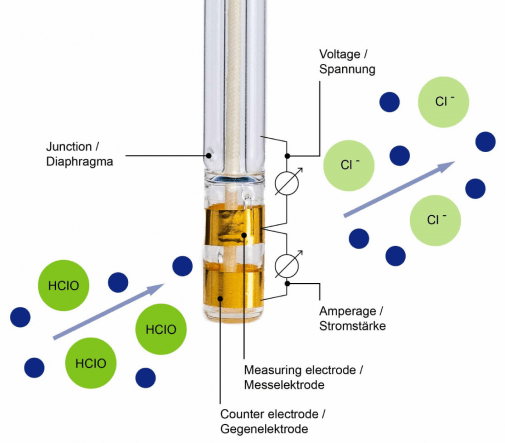

Kuntze sensors enable constant, low-maintenance, and accurate measurement of disinfectants such as free chlorine, chlorine dioxide, ozone, and hydrogen peroxide. Our measurement features an open sensor technology that can be seamlessly integrated into existing measuring systems and can be controlled by software. Kuntze sensors are designed to completely eliminate the need of membranes replacements, electrolyte changes or reagents. Beyond that, no error-prone, moving mechanical parts are installed in our sensors. Our sensors are manufactured exclusively in Germany to the highest quality standards. This results in clear advantages in measurement accuracy and longevity compared to measurements with membrane-covered sensors and online colorimetric measurements. In combination with our proven Automatic Sensor Cleaning (ASR®), Kuntze sensors are reliable even in the most difficult water conditions.

The innovative Automatic Sensor Cleaning system ASR® keeps Kuntze products clean and ready for operation – without adding any chemicals. The highly efficient cleaning process protects against contamination by manganese, iron, grease and lime. During the electrochemical cleaning, adherent deposits are blasted off, organic contaminants are eliminated by the created oxygen molecules, while rust and manganese are removed hydrogen. The cleaning intervals of Kuntze disinfectant sensors can be flexibly adjusted: Depending on the water conditions, you can choose whether cleaning should take place e.g. once or several times a week. The cleaning times are adjustable and can be set to non-critical times. Thus, Kuntze sensors adapt through ASR® to your individual measuring processes.

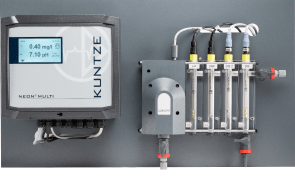

The Krypton® Multi offers precise results in industrial disinfectant applications, e.g. in drinking water plants or food production, thanks to its multi-channel monitoring. The all-in-one system consists of a measuring device, multiple sensors running simultaneously, a flow fitting, software, and cables. In its basic standard configuration, the Krypton® Multi is equipped with three measurements: Disinfection, pH, and temperature. Additionally, a second disinfection, a redox and a conductivity measurement can be added. There are six digital inputs for external events. Eight potential-free output relays can be used either as control or alarm relays. The system features a PID controller and 3-point control functions available with or without feedback. Our modular Argon Stabiflow® fitting is integrated and provides a constant water flow of approx. 30 liters per hour, is brine resistant and approved for pressure up to 6 bar at a temperature of 20 °C.

The Krypton® Multi can be customized to meet your exact measurement and control requirements. With five analog outputs, our unique Automatic Sensor Cleaning (ASR®) as well as a Modbus RTU unit and a data logger are available as add-on modules. The measurement system can be digitally controlled and seamlessly integrated into an existing measurement infrastructure via our Cloud Connect® service. In addition, software updates and add-on modules can be activated at any time after purchase.

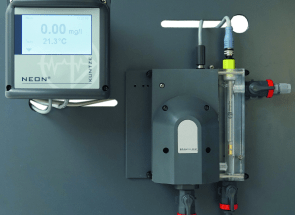

The Krypton® DIS provides reliable measurement results for free chlorine, chlorine dioxide, ozone or hydrogen peroxide and measures the water temperature. The single-channel measurement and control system consists of a measuring device, a sensor, flow fittings, software, and cables. In the standard version, the Krypton® DIS is equipped with a disinfectant and temperature measurement. In addition, there is a digital input and an alarm relay. Our modular Argon Stabiflow® fitting is integrated and provides a constant water flow of approx. 30 liters per hour, is salt and pressure resistant up to 6 bar at a temperature of 20 °C. All measuring parameters and the measuring range can be selected directly via the system’s user interface.

The Krypton® DIS can be extended with additional analog outputs, concentration or volume based control functions, our Automatic Sensor Cleaning (ASR®) as well as a Modbus RTU unit, and a data logger. Full connectivity with an existing measurement infrastructure can be established via our Cloud Connect® service. In addition, software updates and add-on modules can be activated at any time after purchase.

The Krypton® DIS Total is our specialized system for reliable measurement of total chlorine (free and combined chlorine) and water temperature. The single-channel monitoring system consists of a measureing device, a sensor, flow fittings, software, and cables. In the standard version, the Krypton® DIS Total is equipped with a total chlorine and temperature measurement. In addition, there is a digital input and an alarm relay. Our patented, modular Argon Stabiflow® flow fitting is integrated and ensures a constant water flow of approx. 30 liters per hour, is salt and pressure resistant up to 6 bar at a temperature of 20 °C.

The Krypton® DIS Total can also be extended with additional analog outputs, concentration, or volume-based control functions, as well as a Modbus RTU unit and a data logger. Full connectivity with an existing measurement infrastructure can be established via our Cloud Connect® service. Software updates and add-on modules can be activated at any time after purchase.

Connect your Kuntze products via our Cloud Connect® service and discover the possibilities of modern, remote water quality analysis. With our Cloud Connect® dashboard, keep an eye on all you data – in real time and on all devices. In-depth insights into current water quality make it easier to identify patterns and allow you to react faster to critical changes. This increases the efficiency and productivity of your measurement and monitoring activities while reducing maintenance costs.